NHỮNG THỬ THÁCH KHẨN CẤP CỦA VIỆT NAM VÀ THẾ GIỚI

HyNet: a case study on industrial symbiosis

How a collaboration of over 30 organisations across different industries can work together to transition to a low-carbon economy

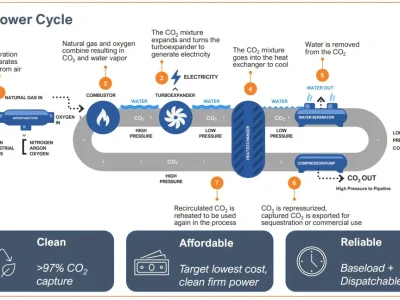

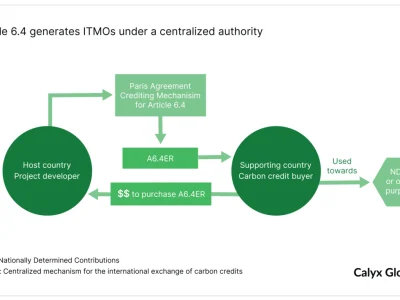

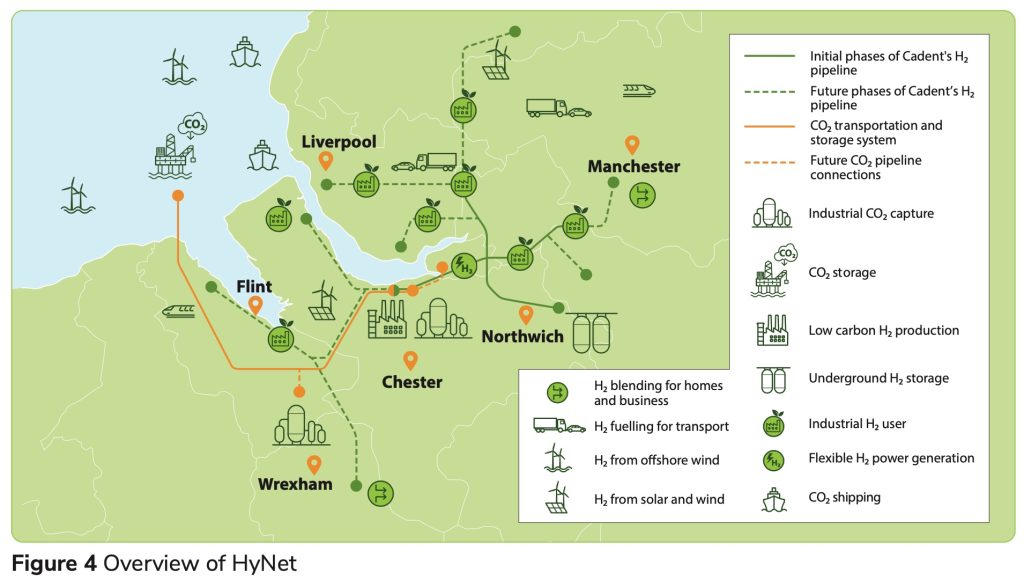

HyNet is a project creating the infrastructure for carbon capture and storage (CCS) and producing, transporting, and storing low-carbon hydrogen. HyNet is a decarbonisation cluster – a project designed to remove and reduce carbon dioxide (CO2) emissions from a regional industrial hub that produces economic output and, subsequently, emits CO2. HyNet and similar clusters across the UK connect companies that generate CO2 and companies that can use low- carbon hydrogen to displace fossil fuel sources such as natural gas. HyNet is a case study on new industrial networks that together can transition to a low-carbon economy.

Background

Progressive Energy was formed in 1998 to deliver hydrogen and CCS clusters and is the architect of HyNet. In this article, HyNet is used as a case study on how a collaboration of over 30 organisations across different industries can work together to deliver an outcome.

A perspective on UK energy consumption

Have you ever thought about how much energy it takes to produce ordinary household tasks? As a consumer, the task of boiling a kettle, a menial element of a Briton’s day, uses on average 2-3 kWh of energy, roughly equivalent to someone climbing the stairs to the top of the Empire State Building! A household gas boiler uses 10 times that energy to provide heating and hot water. The production of energy can be taken for granted.

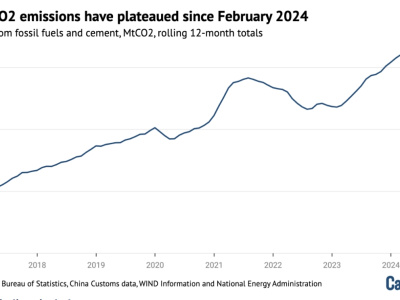

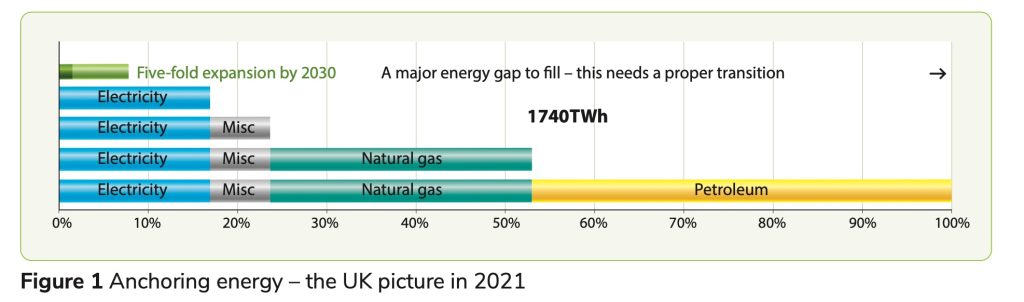

From a national perspective, the UK is one of the world leaders in offshore wind. In 2021, it generated over 30 TWh of electricity from offshore wind, against the UK electricity demand of around 300 TWh. Beyond electricity, natural gas supplies around 600 TWh of our energy, while 800 TWh comes from petroleum products. Thus, while the UK is a world leader in offshore wind, 30 TWh is only 10% of our electricity consumption and just 2% of our total energy flows of 1740 TWh (see Figure 1).

Rightly, the UK plans a massive expansion of offshore wind, but a five-fold expansion would still only make 10% of our total energy flow. So, the question is, how do we fill the gap?

Progressive Energy believes we need renewable energy. For renewables to take a much greater share of the UK’s energy sector, a level of fossil resources will form an inevitable part of our energy system in the short term to transition successfully. And so, projects like HyNet must not only deliver renewable energy into the future but also capture the carbon emissions produced in the short term, targeting hard-to-abate sectors of the economy, such as heavy industry.

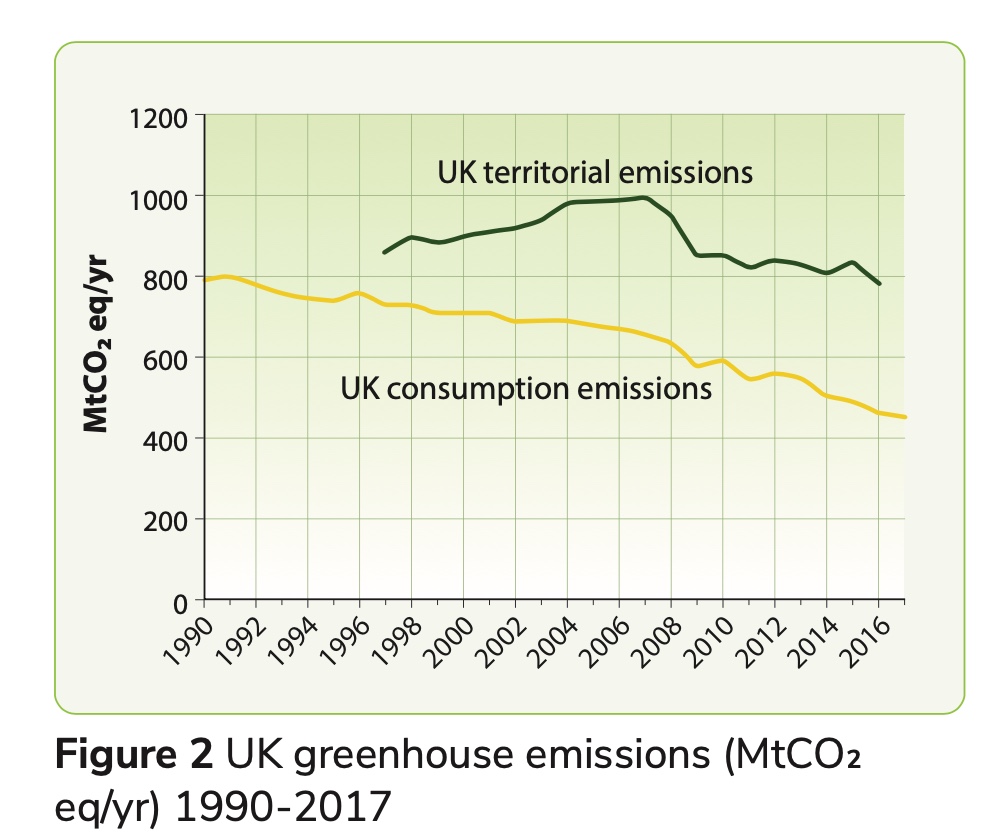

The UK Climate Change Committee monitors the trend in UK greenhouse gas emissions and shows that over the last 25 years, emissions have fallen from around 800 million tonnes of CO2 eq/ yr (0.8 GT) in 1990 to around 450 million tonnes by 2017. However, when the carbon embedded in imported products is factored in, our consumption emissions over the same period have held pretty constant at roughly 800 Mt/yr (see Figure 2). So how can the UK solve this? HyNet will use carbon capture, an almost 50-year-old solution for storing CO2, then transport the CO2 to the depleted oil and gas fields for permanent storage.

HyNet’s foundations

HyNet was conceived around five years ago. The story starts with the demand from industry to contribute to the journey to net zero.

Figure 3 shows the demand for the infrastructure that HyNet is building. Progressive Energy is working with major industrial organisations across the North West to support their switch across to low-carbon hydrogen or capture their carbon emissions.

The driver for this change comes from both business-to-business and end-user consumers recognising that this is not just about decarbonisation but value creation, allowing them to differentiate themselves.

The users of the Hynet infrastructure are given in Figure 3. Around three-quarters of partners and associated companies are looking to decarbonise by fuel switching to low-carbon hydrogen, with some also using the HyNet infrastructure to safely transport and store the CO2 they produce.

Key partners

The location of HyNet gives access to the Liverpool Bay depleted gas fields owned by Eni. This represents a low-cost, low-risk site for CCS (see Figure 4). The gas field is serviced through an existing pipeline, originally used to transport the natural gas from the offshore field, which will be repurposed to deliver the CO2 to the offshore CCS site, shown in orange in Figure 4. The pipeline will be extended to reach the Ellesmere Port industrial zone, with Essar’s refinery located at the Stanlow Manufacturing Complex.

Encirc, the largest bottling plant in the UK, will use locally produced hydrogen to power Encirc’s furnaces, reducing carbon emissions by more than 90%. This will enable the manufacture of billions of low- carbon glass bottles, create over 200 new jobs, and grow a skills base fit for the future to establish the region as the global centre of excellence for glass innovation.

Hanson’s Padeswood cement plant produces CO2 as an inherent part of the cement-making process. The HyNet infrastructure will safely transport and securely store 800,000 t/yr CO2 from this facility.

Fuel switching to hydrogen has been successfully trialled at Pilkington Glass, which created a world first by firing pure hydrogen in its flat-glass manufacturing process. Similarly, Unilever has successfully trialled hydrogen for generating the steam used in its Port Sunlight plant.

Vertex Hydrogen is building a large-scale hydrogen production plant, using Johnson Matthey’s low-carbon hydrogen technology with a conversion efficiency from methane to hydrogen of 85% and a CO2 capturing efficiency of 97%. The captured CO2 will be sent via the pipeline for offshore storage.

Cadent is building a 120km hydrogen distribution pipeline, which will be connected to the storage of hydrogen in underground salt caverns managed by Inovyn, to balance hydrogen supply and demand and give dispatchable power generation that can compensate for the intermittency of renewables, such as wind and solar power. In the longer term, there is potential for hydrogen to be added to the wider natural gas network as a means of decarbonising household gas supplies.

HyNet establishes an infrastructure for all sources of hydrogen, encouraging investments in low-carbon hydrogen from electrolysis (green hydrogen) in this region (see Figure 4).

Next steps

The HyNet project is now moving from the development to the delivery phase. The Vertex hydrogen production facility has already gone through front end engineering design (FEED), and planning permission has been submitted. The Cadent hydrogen distribution pipeline is already in FEED, and consultation is taking place. Inovyn has almost finished the FEED for the hydrogen storage, and soon 1.3 TWh of hydrogen storage will have gone through FEED and consenting. Eni is also at an advanced stage in its engineering and consenting process. HyNet will be able to store 10 MT CO2 annually by 2030, while almost 50% of the region’s natural gas can be displaced by hydrogen.

The project will create an estimated 6,000 new green jobs and help diversify the economy. This is an opportunity for economic redevelopment in the North West and Wales and could support 75,000 jobs. HyNet represents the UK’s first net- zero industrial cluster. The project will not only build on the region’s rich industrial heritage with an estimated economic impact of £17 billion for the North West and North Wales but also reduce the region’s carbon emissions by a quarter within five years.

Author: Chris Manson-Whitton

![NGUYỄN ĐÌNH QUYỀN [VN]](https://carbonhub.vn/wp-content/uploads/NGUYEN-DINH-QUYEN-VN-400x300.png)